Chemical recycling technologies of used tires

Work towards a low-carbon, recycling-oriented society

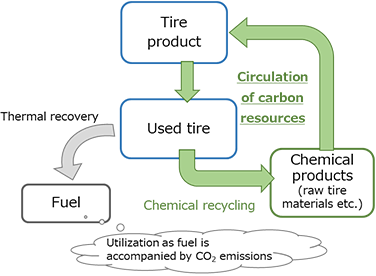

Research and development efforts to achieve carbon neutrality are accelerating around the world. Used plastics and rubber are utilized as fuel in Japan, mainly through thermal recovery, but this process consequently results in CO2 emission. Utilizing renewable resources is indispensable to the development of a low-carbon, recycling-oriented society.

ENEOS Corporation is developing “chemical recycling technologies that enable precise pyrolysis of used tires” in collaboration with Bridgestone Corporation. Through this initiative, we aim to significantly reduce CO2 emissions and increase resource circulation (Fig. 1).

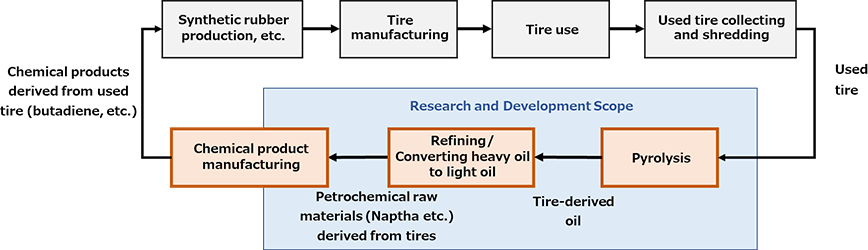

Chemical recycling process

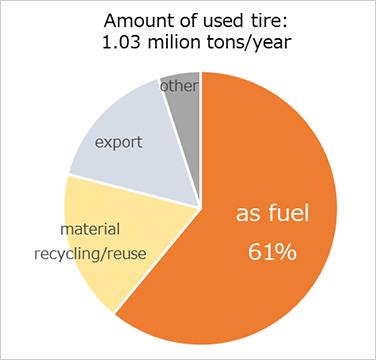

(Source: The Japan Automobile Tyre Manufacturers Association, Inc.)

The demand for tires is expected to grow in the future alongside rising automobile and transportation demands. Synthetic rubber derived from petroleum is one of the primary materials used in tire production. Used tires are also utilized as fuel in Japan, mainly through thermal recovery (Fig. 2). If the implementation of “chemical recycling technologies that enable precise pyrolysis of used tires” can be made into a reality, it should help contribute to reduced CO2 emissions and increased resource circulation.

In our chemical recycling process under development, used tires are converted into petrochemical raw materials (such as naphtha) through precise pyrolysis and refining / light oil conversion. From these materials, chemical products such as butadiene, which is a raw material utilized in synthetic rubber, are produced in high yield from the petrochemical raw material derived from used tires (Fig. 3). We will establish chemical recycling technology for used tires by utilizing our crude oil refining technology and basic technology related to the manufacturing of basic chemicals.

We will continue this development in our effort to achieve a sustainable society.