Biofuels

Production of Cellulosic Bioethanol for a Decarbonized Society

From the viewpoint of reducing carbon-dioxide (CO2) emissions, bioethanol is expected to be used in applications such as automobile fuel and raw material for chemical products. In recent years, using bioethanol as a raw material for producing aviation fuel has also attracted attention.

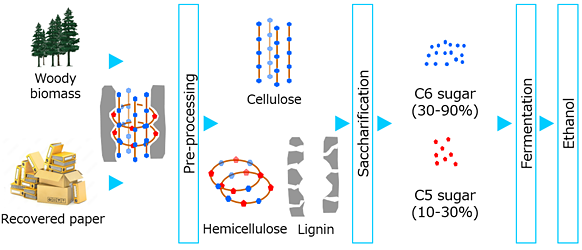

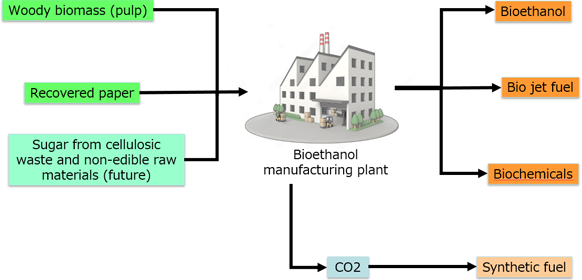

Currently, bioethanol is mainly produced in the world from food crops such as sugarcane and corn, so it is a concern that it may compete with food. Given that situation, ENEOS is developing technology for producing bioethanol by using—as raw materials—woody biomass (such as pulp) and cellulose resources (such as recovered paper) that cannot be used as food (Figure A).

Development of continuous ethanol-production process for practical use and advanced utilization of CO2

ENEOS is developing a process for the practical application of cellulosic bioethanol. Aiming to increase the efficiency of utilization of raw materials, ENEOS has developed—as an elemental technology—a proprietary yeast that can utilize xylose, which is difficult to convert with conventional yeast. Our continuous ethanol-production process combines the following processes in a manner that reduces production costs: (i) efficient pretreatment, (ii) saccharification and fermentation using the proprietary yeast, and (iii) recovery and circulation of enzymes (which break down woody biomass) and yeast (which produces ethanol). In addition to performing basic studies at the laboratory level, a 100-kL/year demonstration plant using this process has been successfully operated, and the world’s first* continuous production of ethanol (for more than 20 days) was demonstrated. Moreover, it was confirmed that producing bioethanol by using this process emits less CO2 than combustion of fossil-fuel resources. Currently, targeting social implementation of cellulosic bioethanol, ENEOS is studying diversification of raw materials, increasing the efficiency of ethanol production, and further reducing CO2 emissions. Applying the knowledge gained from the demonstration plant, we are also examining the possibility of scaling up the plant as well as continuing technological development with the aim of operating a commercial-scale plant in 2027 or later.

- According to a company survey

Bioethanol plants emit CO2 as a result of ethanol production (Figure B). This CO2 can be recovered and used as a raw material for synthetic fuels; consequently, our continuous ethanol-production process is even more effective in reducing CO2 emissions in total.

In the future, ENEOS will contribute to the creation of a low-carbon society by commercializing cellulose bioethanol manufacturing technology and using that cellulosic bioethanol as fuel for automobiles, aviation fuel, and raw material for manufacturing chemicals.