Refrigeration Oils for Use with Eco-Friendly Refrigerants

Refrigerating machine and refrigeration oil

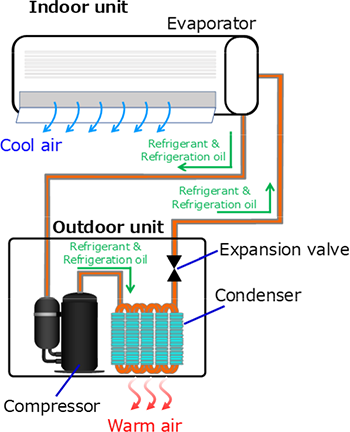

A refrigerating machine is a device that produces low temperatures by transferring heat. For example, room air conditioner and refrigerator. Most common refrigerating machines are made up of a compressor, a condenser, a thermal expansion valve, and an evaporator (Figure 1). A refrigerant circulates through the system, absorbing heat and then releasing heat repeatedly as it undergoes compression, condensation, expansion, and evaporation. This is called the refrigeration cycle.

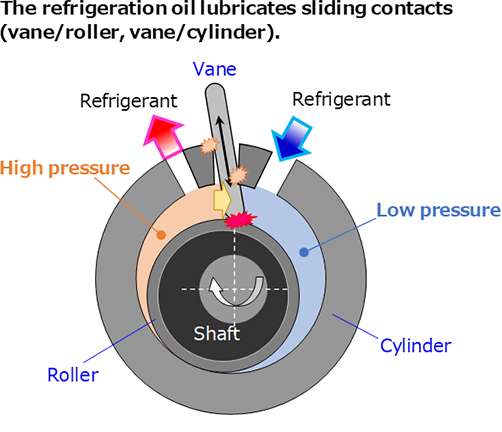

A compressor serves as the "heart" in this cycle, pumping the refrigerant through the system. A refrigeration oil is what lubricates the sliding parts inside the compressor (Figure 2).

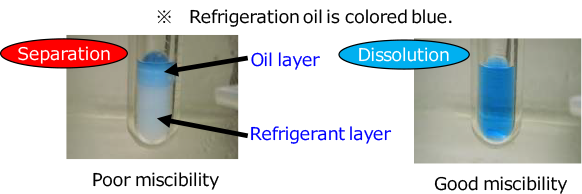

Refrigeration oil is discharged from the compressor along with the refrigerant. The refrigeration oil needs to circulate through the refrigeration cycle and return to the compressor without building up and blocking the lines so that a suitable level of oil is maintained inside the compressor. For this to be possible, the refrigeration oil must be sufficiently soluble in the refrigerant (miscibility with refrigerant). Aside from lubricity, oil-refrigerant miscibility is one of the key performance requirements for a refrigeration oil.

Development of refrigeration oils for use with R32

Different types of refrigerating machines require different refrigerants, and the refrigerant used will dictate the type of refrigeration oil that can be used. Recent years have seen a trend towards more eco-friendly refrigerants. The HCFC (hydrochlorofluorocarbon) based R22 had been used as a refrigerant for room air conditioners. But because R22 is known to deplete the ozone layer, it has steadily been replaced by the HCF (hydrofluorocarbon) based R410A for this application. However, R410A still has a high Global Warming Potential (GWP) of 1975, meaning it absorbs 1975 times more heat in the atmosphere than an equivalent mass of CO2. There has thus been an ongoing switch to the more eco-friendly R32 (GWP: 675). We have developed and launched refrigeration oils that are compatible with R32 (Figure 3).

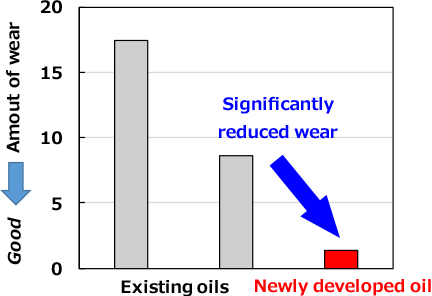

In addition, we are moving forward with research and development of refrigeration oils that provide more lubrication to the sliding parts in compressors, thus reducing wear and improving reliability. We've also developed an effective method for evaluating oils using an actual compressor that we're using to develop refrigeration oils that provide increased lubricity and reduce wear (Figure 4).

In developing and marketing refrigeration oils for use with eco-friendly refrigerants, we contribute to protecting the environment.