Chemical recycling

Toward a carbon-neutral society

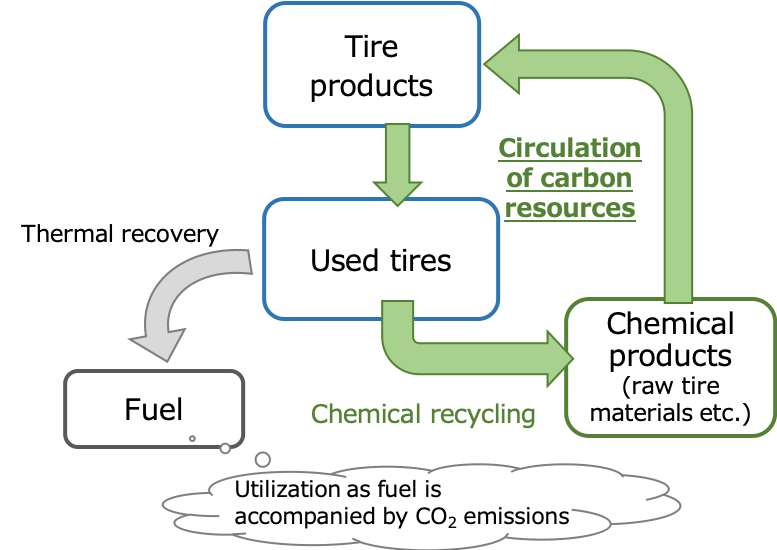

Initiatives to achieve carbon neutrality are accelerating around the world. Most post-use plastic and rubber products are effectively used as fuel through thermal recovery, but this process results in CO2 emissions. Promoting the use of renewable resources is crucial for realizing a carbon-neutral society.

ENEOS, in collaboration with Bridgestone Corporation, is developing a set of technologies for “chemical recycling technologies that enable precise pyrolysis of used tires”. This initiative is part of our efforts to further reduce CO2 emissions and improve the circulation of resources (Figure 1).

Recycling process

The demand for tires, a product familiar to all of us, is expected to increase along with the growing needs for automobiles and transportation. Synthetic rubber derived from petroleum is one of the main materials in tires, and most used tires undergo thermal recovery. Implementing a “Chemical recycling technologies that enable precise pyrolysis of used tires” process would contribute to reducing CO2 emissions and promoting renewable resource use.

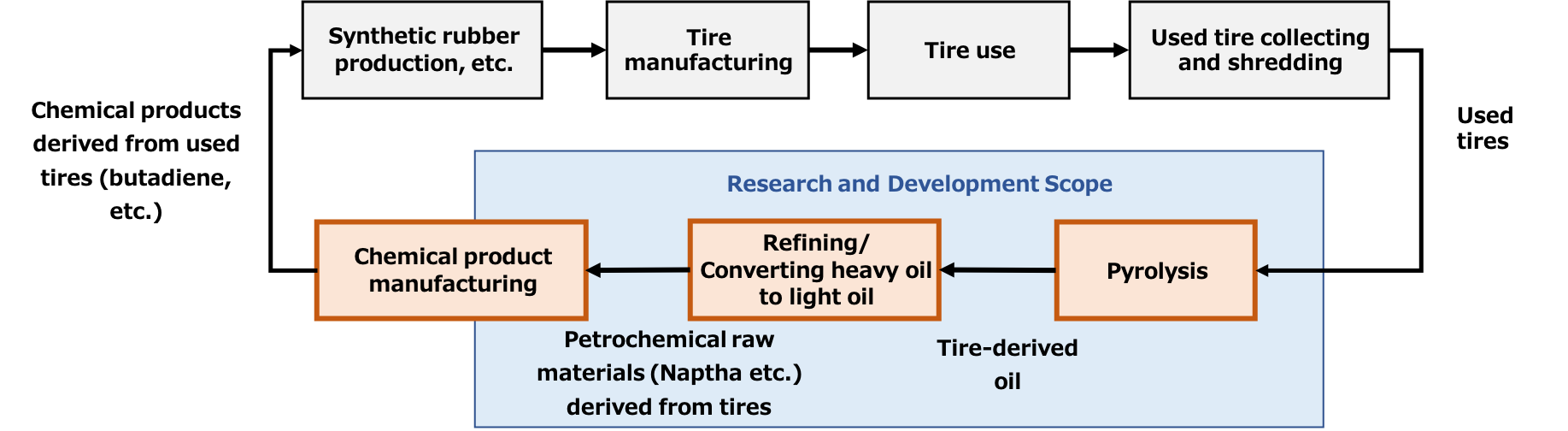

In our recycling process currently under development, the cracked oil obtained by precise pyrolysis of used tires is converted into petrochemical raw materials such as naphtha, which are then used to produce chemical products including butadiene, a raw material used in synthetic rubber, in high yield (Figure 2).

By leveraging our expertise in crude oil refining and basic chemical manufacturing, ENEOS aims to establish a chemical recycling technology for used tires.

We will continue in these development efforts to realize a carbon-neutral society.