Using plastic waste in asphalt

Demonstration test has begun!

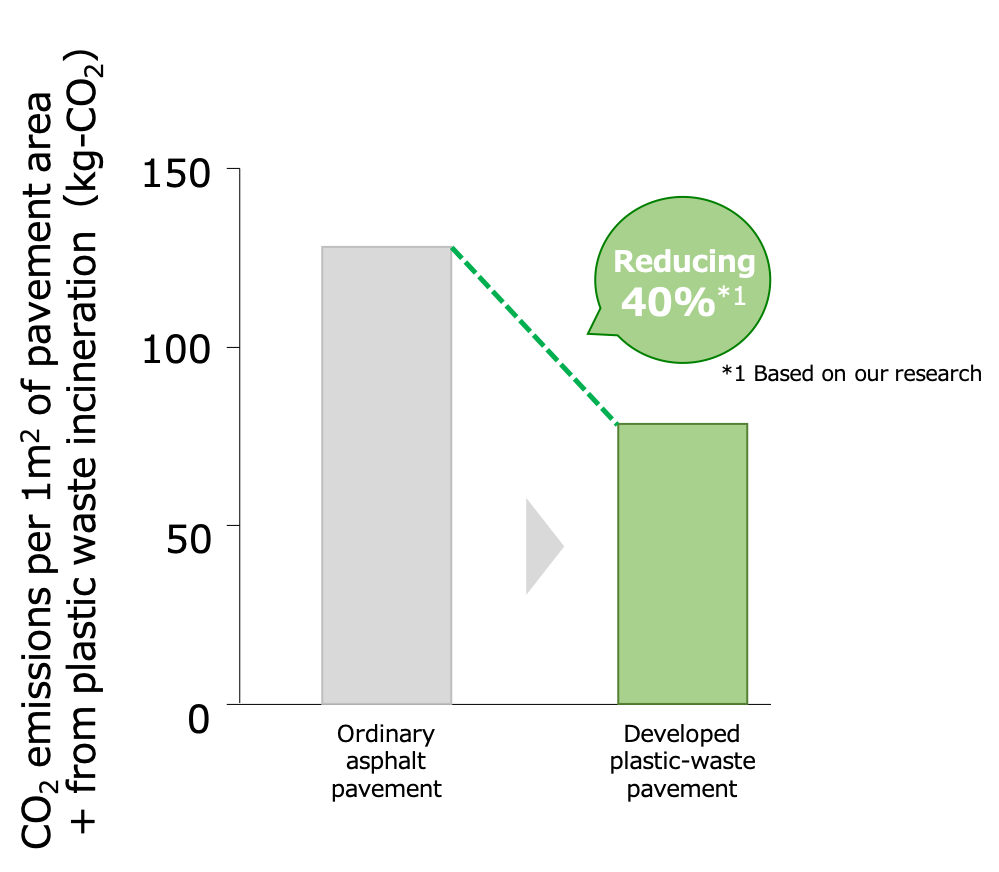

ENEOS has begun demonstration tests on a new type of asphalt pavement using plastic waste that can significantly reduce CO2 emissions toward a carbon-neutral society at several internal/external sites (Figure 1). Calculations have shown that this technology, in addition to contributing to the recycling of plastic, has the effect of reducing CO2 emissions by approximately 40% compared with conventional pavement (Figure 2).

More than 7 million tons or nearly 90% of all plastic waste discharged in Japan is recycled in one form or another. However, the recycling of post-use-products (material recycling), the most popular image of recycling, is no more than 20% of all recycling. In actuality, the processing of most plastic waste is dominated by thermal recycling that recovers part of the heat produced as a by-product of incineration. We have developed a new type of pavement material that directly uses the characteristics of plastic waste as much as possible without relying on burning. Upgrading the recycling process from thermal to material in this way will help promote the circulation of resources.

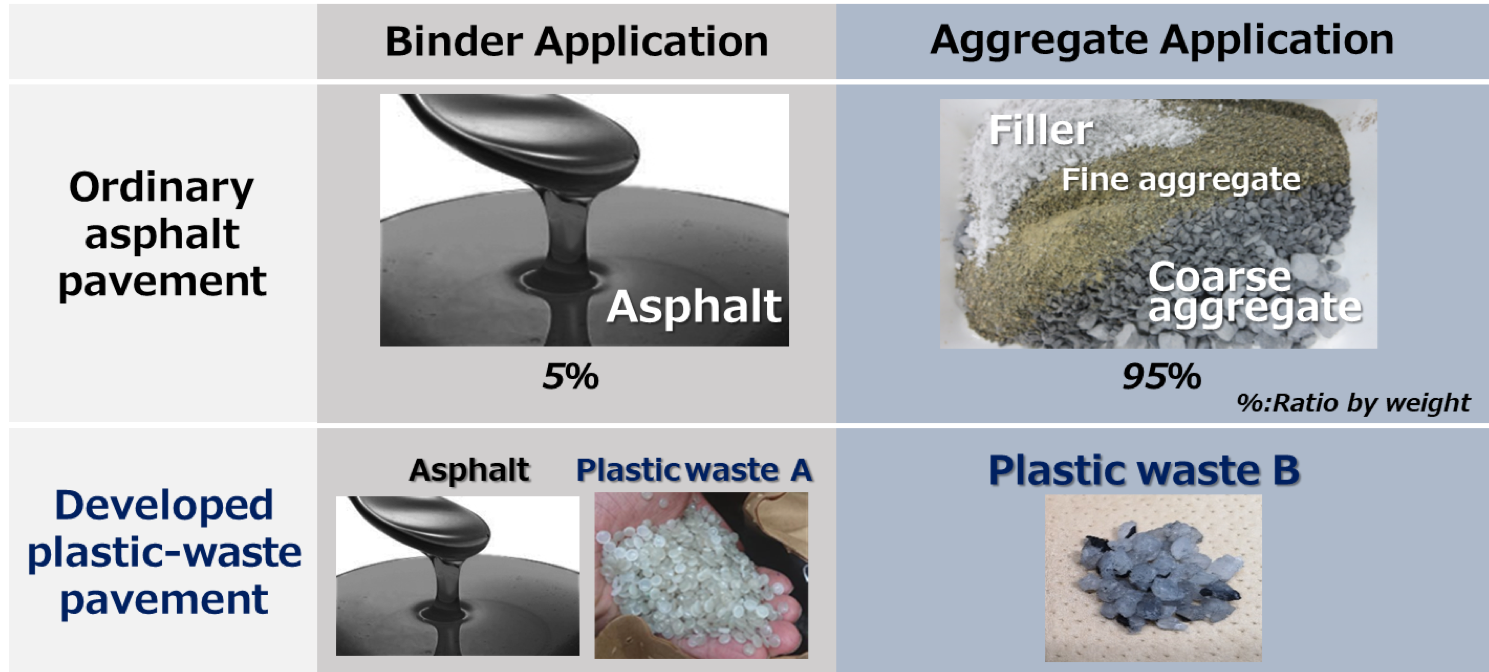

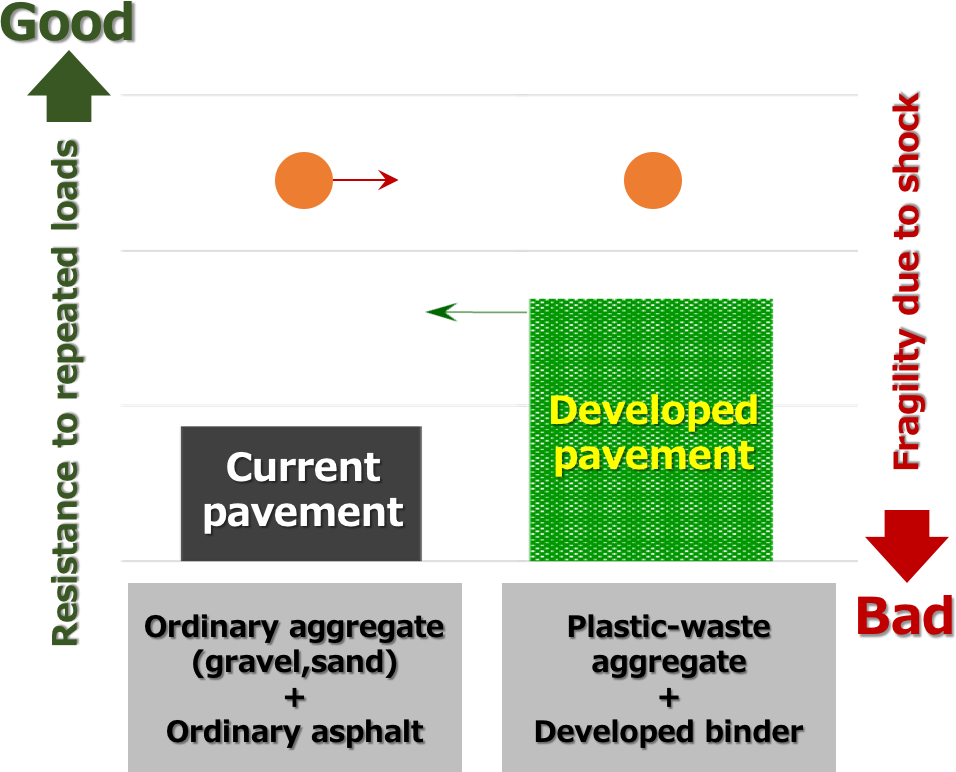

Road pavement is commonly referred to as “asphalt,” but most of it consists of materials like gravel and sand as an aggregate (Figure 3). In addition to using plastic waste to improve the functional abilities of asphalt as a binder, replacing the entire amount of the aggregate of gravel, sand, etc. with plastic waste will enable much more of it to be used. However, the surface of plastic is smooth, so deformation of the pavement body called “wear rut” can easily occur. It is therefore necessary when using plastic waste as aggregate to improve the functional abilities of the asphalt. We therefore strengthened the flow resistance of the asphalt by using plastic waste having characteristics applicable to this need and confirmed that the developed pavement could demonstrate equivalent or greater performance than current pavement even if using plastic waste for the aggregate (Figure 4). Additionally, for the aggregate, we devised a model case using cross-linked polyethylene widely used as insulating material for power lines as a material that satisfies many requirements including high heat resistance. We are now studying this model with the aim of putting it to practical use. In addition to excelling in environmental performance, this technology can greatly reduce weight thereby alleviating performance requirements of roadbed materials and elevated structures that support the pavement body as well as contributing greatly to a reduction in material transport costs. We can expect proposals of new construction methods making use of this material lightness.