Development of new materials using Materials Informatics (MI)

Development of new materials using MI

Materials Informatics (MI) is a game-changing technology, fueled by massive amounts of data, that propels Artificial Intelligence (AI) forward in the search for novel materials. It has been attracting attention in many countries due to its emerging status as an essential technology of the future.

ENEOS aims to discover and develop innovative materials through the integration of experiments, simulations, and AI in investigating such fields as renewable energy, catalysts, lubricants, and high-performance materials.

AI × Simulation Platform: Development and Application of MatlantisTM

There is a growing search for innovative materials to help achieve carbon neutrality. Existing digital technologies such as molecular simulation and AI are becoming increasingly important. ENEOS and Preferred Networks, Inc. have jointly developed MatlantisTM: a versatile atomistic level simulator. MatlantisTM can calculate the energy and physical properties of molecules, crystals, and other types of materials at extremely high speeds and search for a wide range of new materials beyond what was possible in the past.

Preferred Computational Chemistry, Inc. (PFCC) was founded by both companies, and has been providing MatlantisTM under a Software as a Service (SaaS) model since 2021 in Japan. Furthermore, the service has also been provided in the US from April 2023 and in Europe from December of the same year. We are contributing to the development of new materials around the world.

Case studies of using MatlantisTM and MI

ENEOS has taken up the challenge of accelerating materials research and fostering innovation in R&D using MatlantisTM.

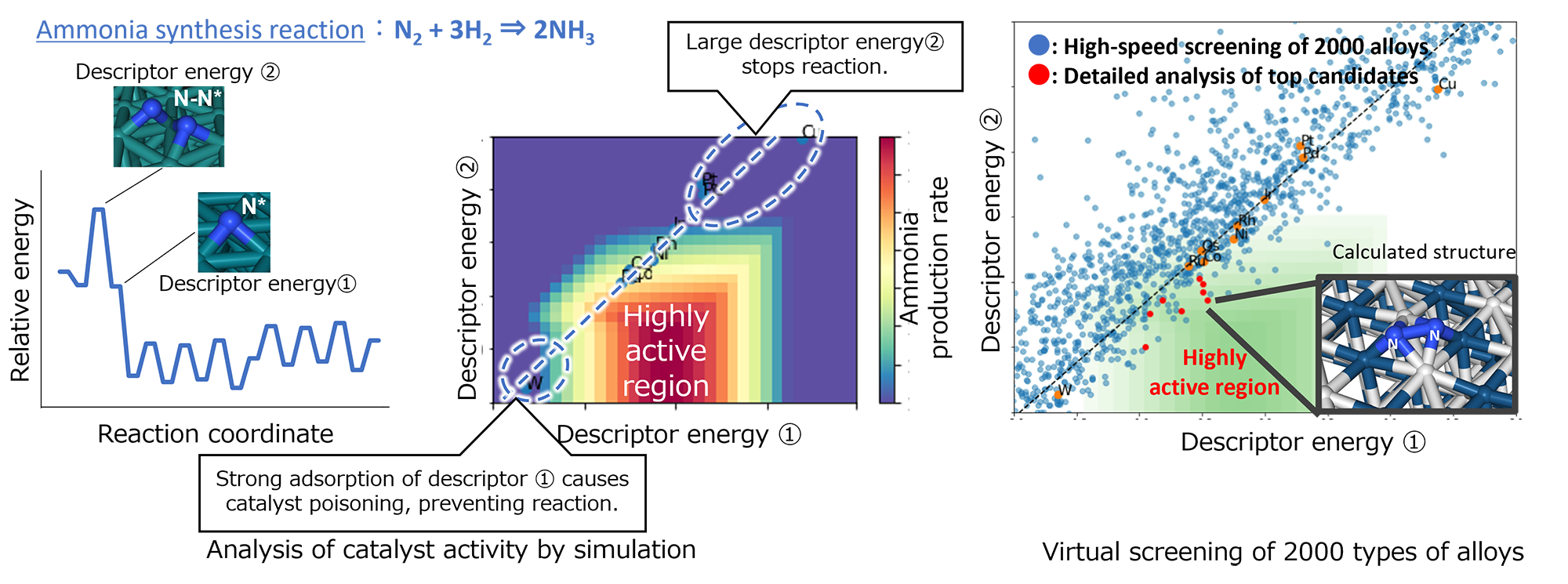

(1) Virtual searching of catalysts for ammonia synthesis

Through chemical simulations, this process calculated the activation energy (indicating the ease of reaction progression) and the adsorption/desorption energies for reactions occurring on various catalyst surfaces. The results are analyzed using machine learning and AI, enabling the design of catalysts with higher functionality than those obtained by conventional methods.

MatlantisTM has allowed researchers to conduct virtual screening without the need for physical experiments, leading to the discovery of promising potential candidate materials.

(2) Design of lubricants and grease

This process designs lubricants and grease using simulation technologies such as MatlantisTM to enable the creation of high-efficiency and high-performance mechanical systems with low environmental load.

To achieve this goal, researchers simulate candidate products in order to obtain an understanding of molecular structures that enhance the adsorption of additives. This investigation ultimately allows researchers to increase low-friction and anti-wear properties or clarify the chemical reactions that play an important role in preventing wear on materials.

Through these simulations, ENEOS is working tirelessly to design the ideal forms that lubricants and grease should take to achieve optimal tribological properties. (Click here for the Lubricants R&D page)

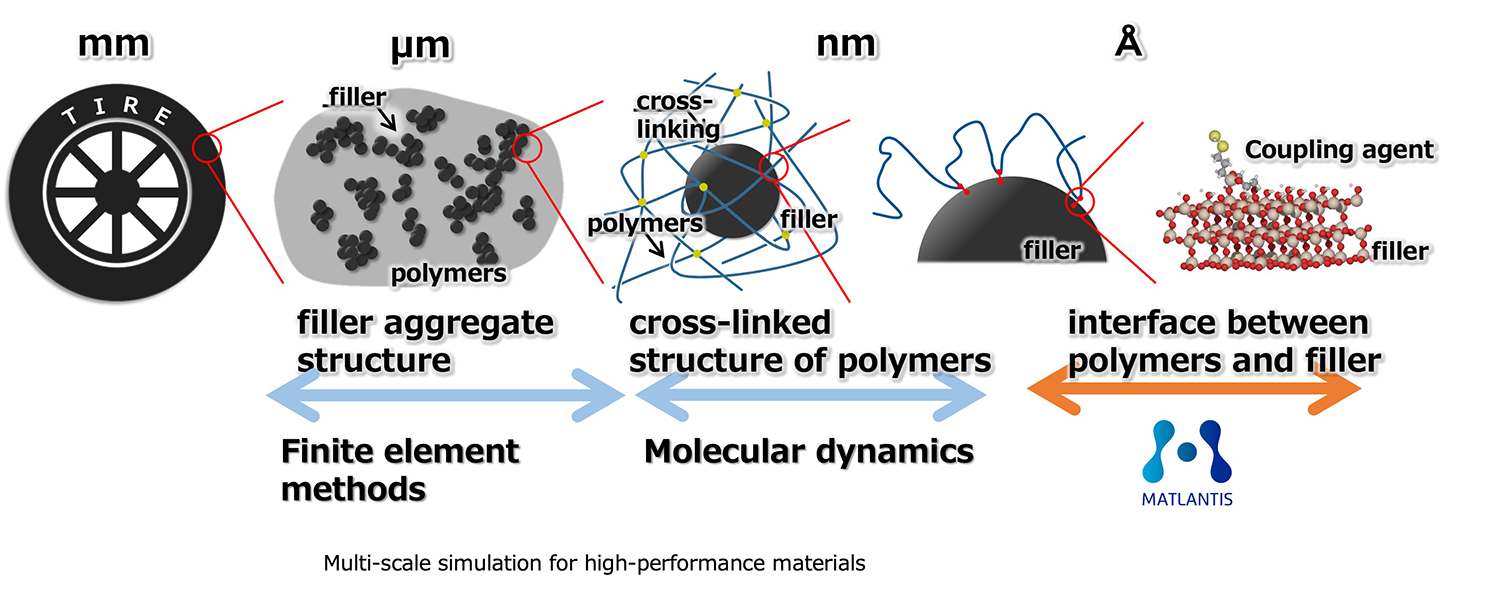

(3) Multi-Scale Simulation × AI for developing tire rubber material

ENEOS uses various simulation technologies alongside MatlantisTM to target various scales, such as the finite element method for the mm scale, and coarse-grained molecular dynamics simulations for the μm scale. These methods ultimately serve to develop rubber materials with complex hierarchical structures for use in producing resilient, high-quality tires. The combined efforts of simulations and machine learning (AI) are currently driving the development of materials to further improve tire performance.

(4) Linked with the reaction auto-search program “GRRM20”

Our company, alongside HPC SYSTEMS and PFCC, have jointly developed GRRM20 with Matlantis. GRRM20 with Matlantis uses GRRM on MatlantisTM to complete the automatic exploration of chemical reaction pathways at an unprecedented speed.