Industrial lubricants

Industrial lubricants that play an active role in manufacturing

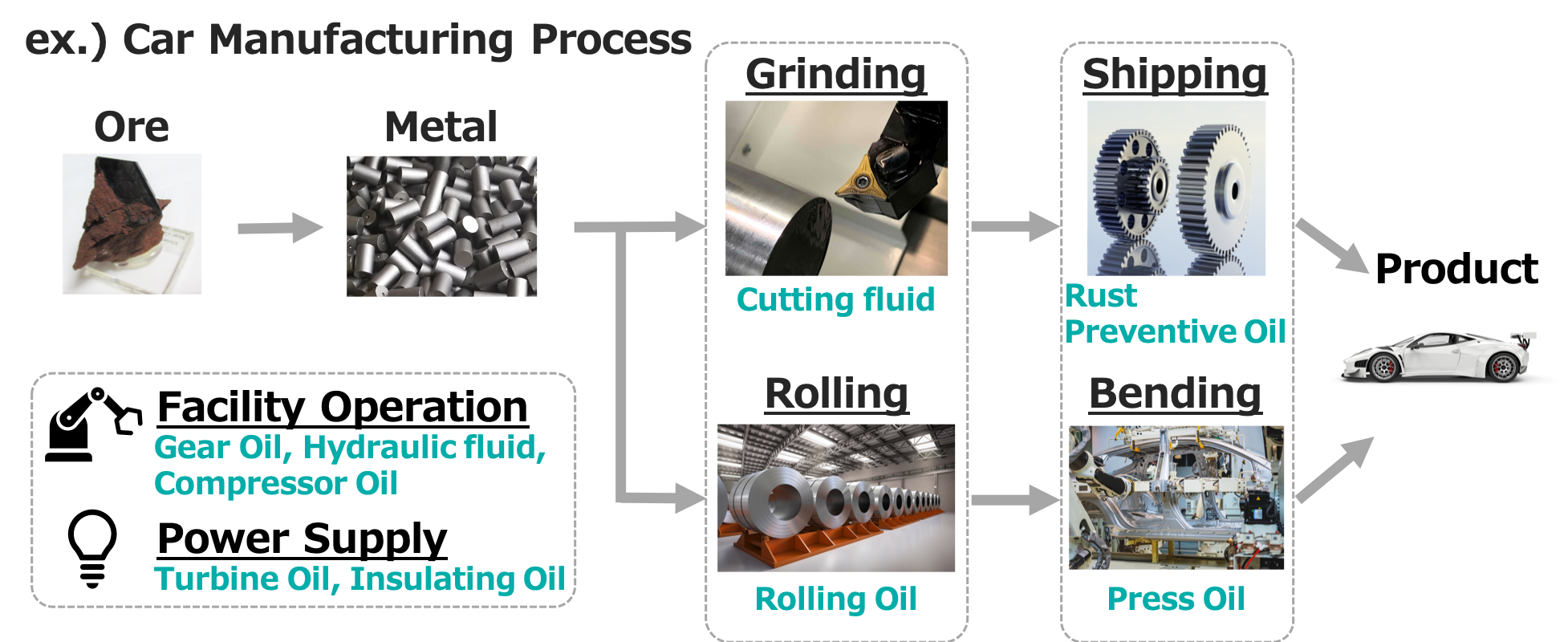

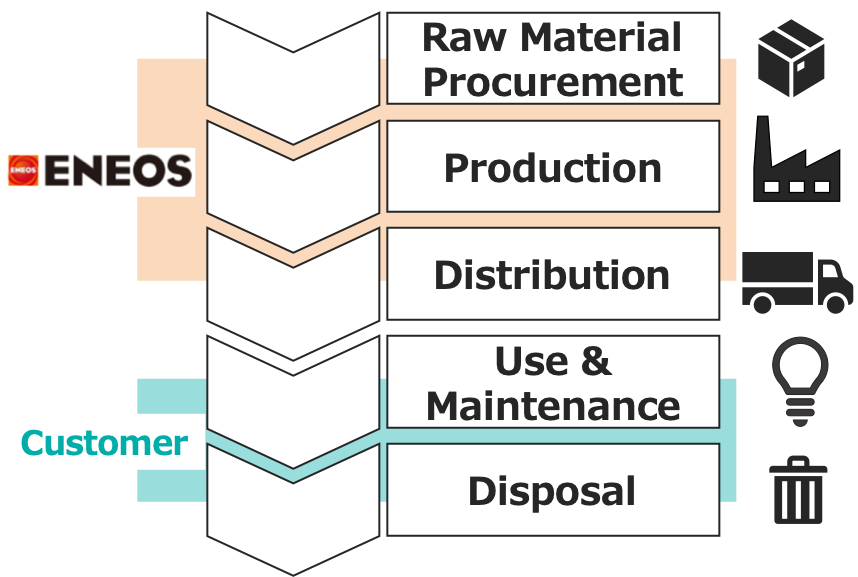

Lubricants are indispensable to manufacturing, as they lubricate and operate a variety of machines when manufacturing products from raw materials (Fig 1).

Toward carbon-neutral manufacturing

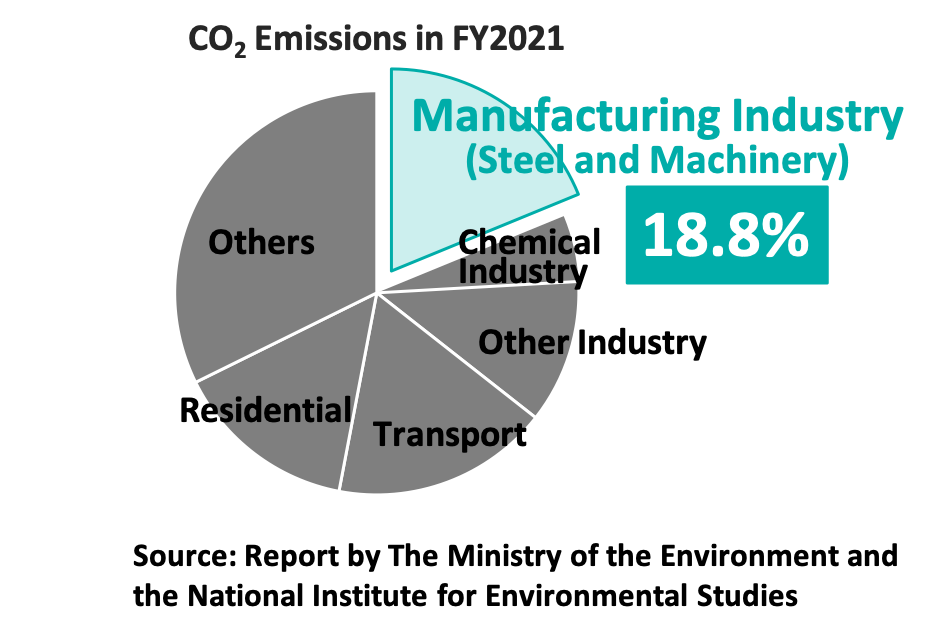

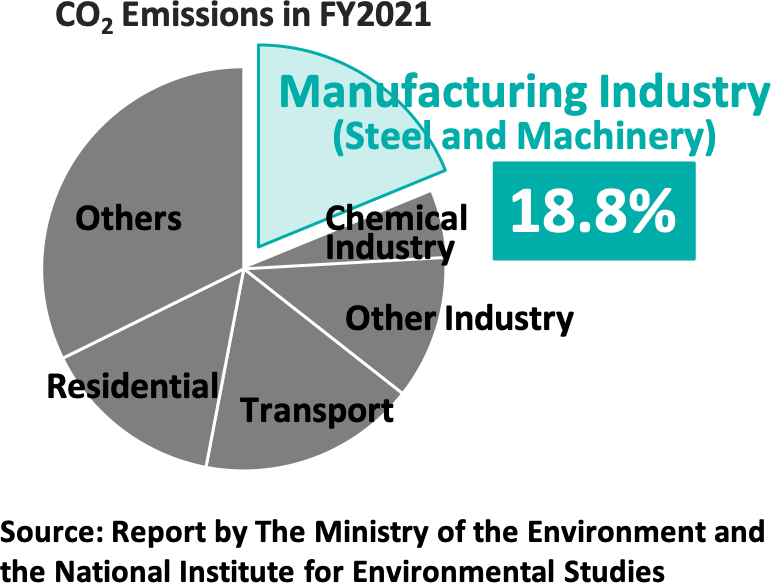

The manufacturing field emits a large amount of CO2 accounting for 18.8% of total CO2 emissions in Japan according to 2021 data (Fig. 2).

We believe that lubricants, which play an essential part of manufacturing, can contribute to carbon neutrality.

To reduce CO2 emissions even further, ENEOS proposes “energy-saving lubricants” not only for making our in-house processes carbon neutral but also for reducing the amount of energy used by customers in manufacturing products (Fig. 3).

Energy-saving hydraulic fluids

Hydraulic fluids are pressure transmitting medium used for operation of hydraulic machinery. They are widely used in construction equipment such as excavators, factory machineries, and machine tools (Fig. 4).

Focusing on friction loss, ENEOS has adopted high-performance friction modifiers to achieve low-friction in sliding parts. Improved products using biomass base oils are also on sale (Fig. 5).

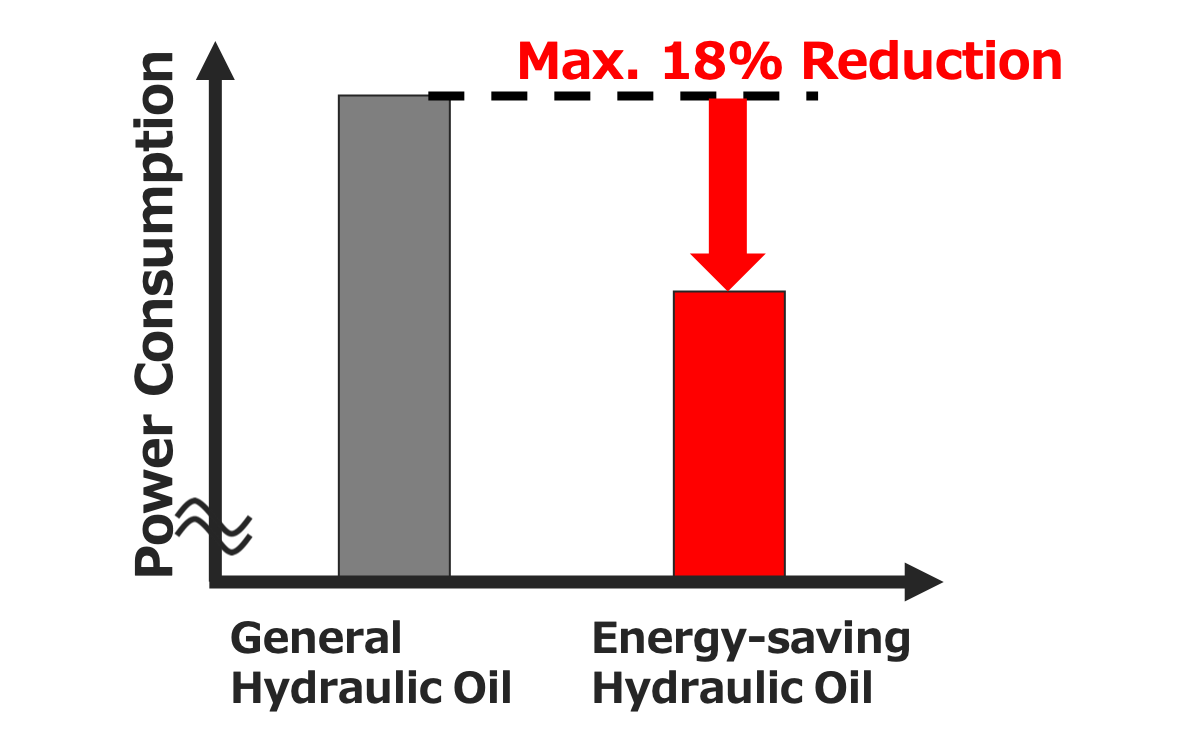

ENEOS energy-saving hydraulic fluids have been successful in reducing power consumption in customer equipment by a maximum of approximately 18% compared to conventional products (Fig. 6).

Energy-saving metalworking fluids

In processing that stretches or changes the shape of material by applying a load, metalworking fluids are used to reduce friction between the material and tools and prevent tool wear and seizure (Fig. 7).

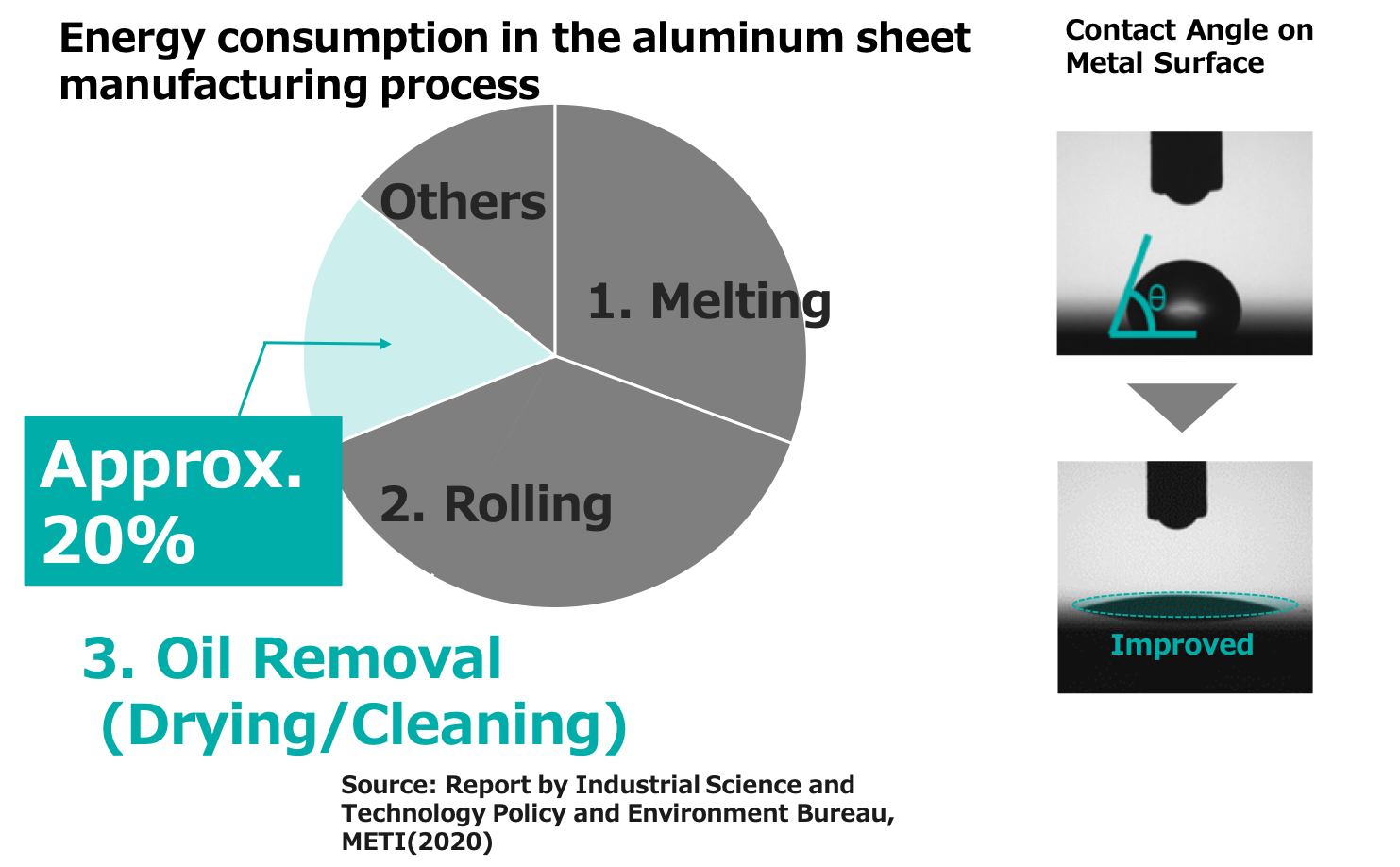

In a rolling process, approximately 20% of the energy used is consumed in removing lubricants (Fig. 8). ENEOS has designed an “easy-to-dry” lubricant having high volatility and wettability.

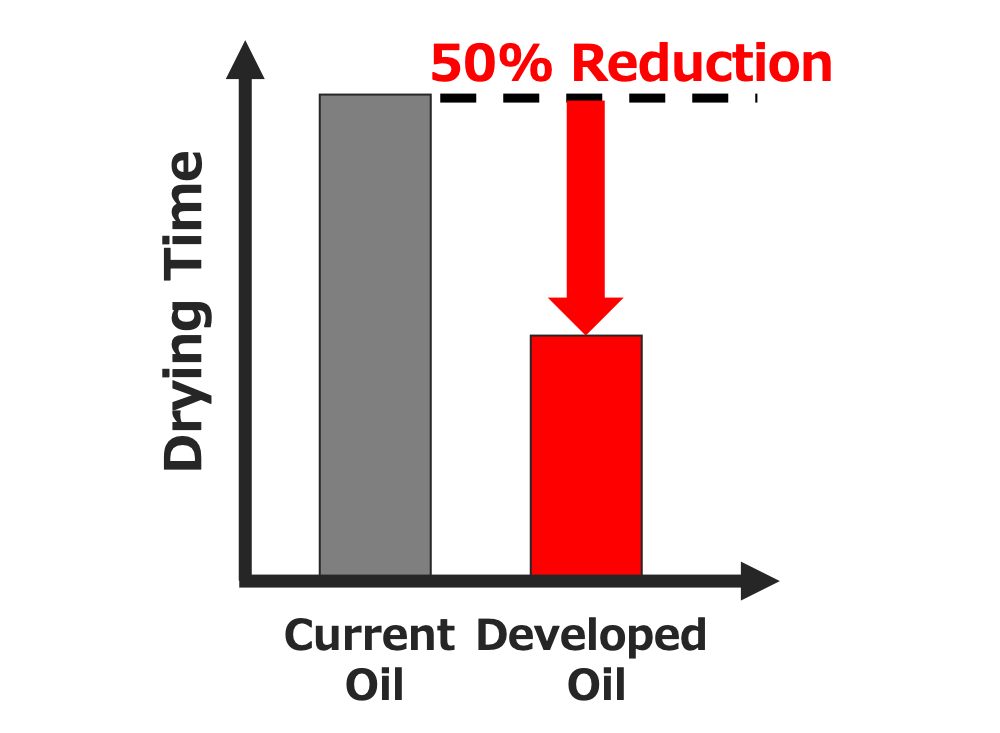

With this lubricant, we have successfully shortened drying time by 50% compared to the current product (Fig. 9).