Driving demonstration of Vehicles Running on Synthetic Fuels at the Expo 2025 Osaka, Kansai, Japan

Synthetic fuels are a key option for achieving carbon-neutral mobility

“Synthetic fuels” are carbon-neutral fuels synthesized from hydrogen and carbon-dioxide(CO₂) derived as raw materials from renewable energy sources. It achieves carbon neutrality thanks to reduced CO₂ emissions throughout its entire lifecycle—from raw-material production to product use. Aiming to create a decarbonized society, we are developing technology for production of synthetic fuels, which represents a key part of our next-generation energy business. We are producing synthetic fuels at a plant completed at our Central Technical Research Laboratory in 2024 and supplying diesel and gasoline blended with these synthetic fuels during the Expo 2025 Osaka, Kansai, Japan (hereinafter “the Expo”). We promote the idea that engine-equipped vehicles running on synthetic fuels are a key mobility option on the path toward carbon neutrality. In addition, it will contribute to achieving the Expo’s sustainability mission as laid out in the EXPO 2025 Green Vision.

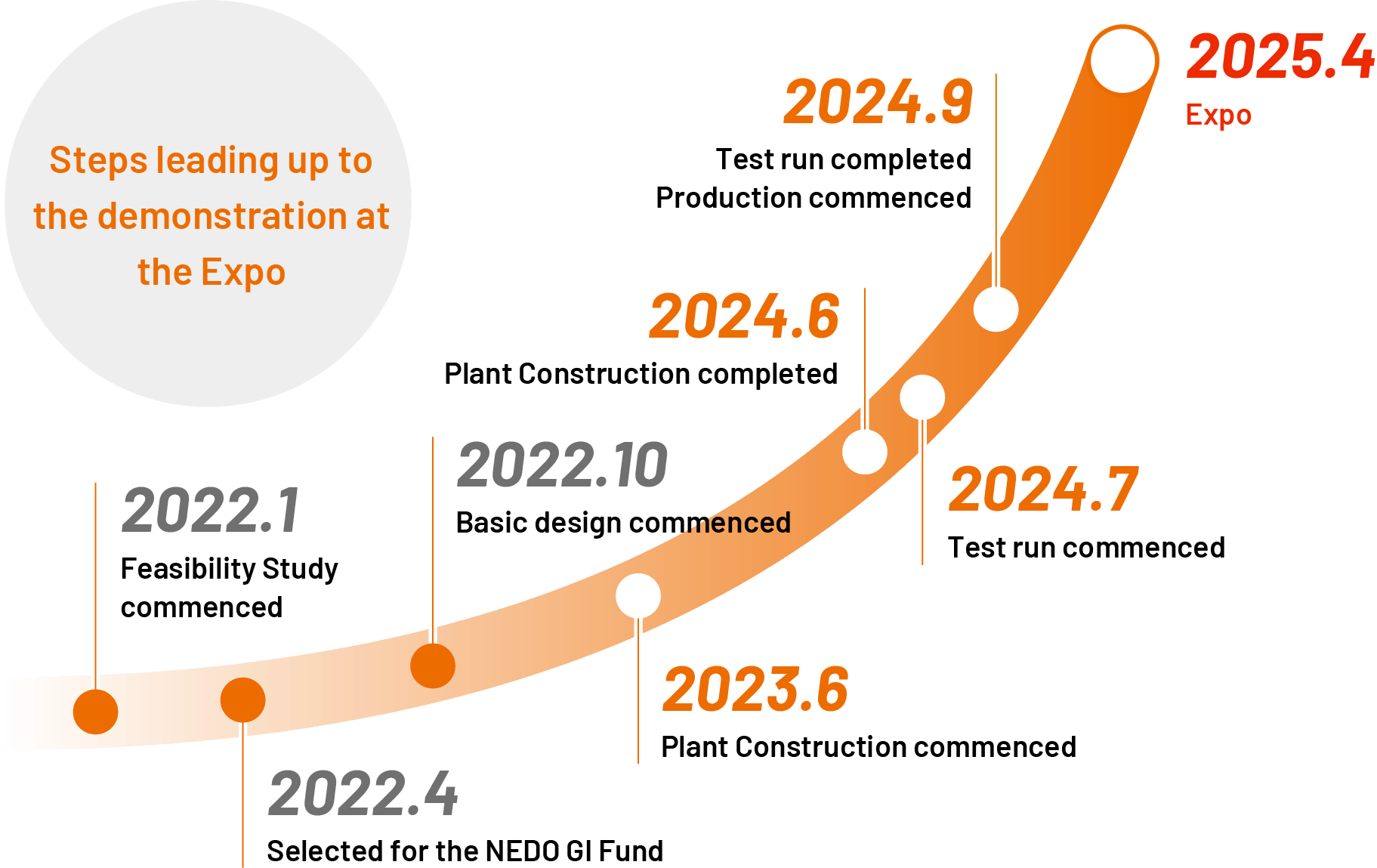

Steps leading up to the demonstration at the Expo

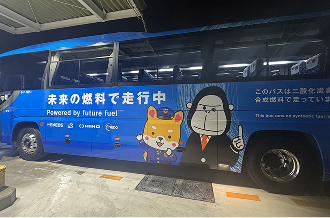

A shuttle bus running on synthetic diesel transports Expo visitors

One of the vehicles running on synthetic fuel at the Expo is a shuttle bus (hereinafter “Expo Shuttle Bus”) from the station to the Expo site. During the Expo, a direct shuttle bus running on synthetic diesel operates between Osaka Station (Umekita Green Place bus parking lot) and the Expo venue. This service is the first time in Japan that synthetic fuel produced entirely from hydrogen and CO₂ is used to operate a commercial vehicle. Our plan is to add a small amount of synthetic fuel to diesel initially and then gradually increase the proportion of synthetic fuel. Through the operation of the Expo Shuttle Bus, we hope passengers and everyone we encounter along the route will experience the potentials of future fuels and showcase a future in which synthetic fuels become widely adopted.

Partners: WEST JAPAN JR BUS COMPANY, and HINO MOTORS, LTD.

After dropping off the last passengers, the bus returns to the garage in the evening.

Refueling for tomorrow’s service.

The bus is cleaned inside and out every night.

The synthetic fuel dispenser is the same type as a conventional diesel dispenser.

Vehicles working on synthetic gasoline for guests and related parties

As well as demonstrating the Expo Shuttle Bus, we are providing gasoline blended with synthetic fuel for the vehicles used for transporting guests and related parties. Synthetic gasoline manufactured at the Central Technical Research Laboratory is being supplied to a total of eight passenger vehicles provided by five car manufacturers. Each manufacturer has confirmed that their vehicles can run on this synthetic fuel just like conventional gasoline. Another advantage of synthetic fuels is that they can be handled with the same facilities as used for storage and transportation of conventional petroleum-based products. During the Expo, synthetic fuel will also be provided at service stations in Osaka city via the same equipment and procedures used for petroleum-based gasoline.

Partners: Suzuki Motor Corporation, Subaru Corporation, DAIHATSU MOTOR CO., LTD. , Toyota Motor Corporation, and Mazda Motor Corporation

Toyota: Vellfire HEV Z PREMIER

MAZDA: CX-80 PHEV

Suzuki: SPACIA HYBRID X

Subaru: CROSSTREK S:HEV

DAIHATSU: ROCKY Premium G HEV

The process leading up to practical use of synthetic fuels

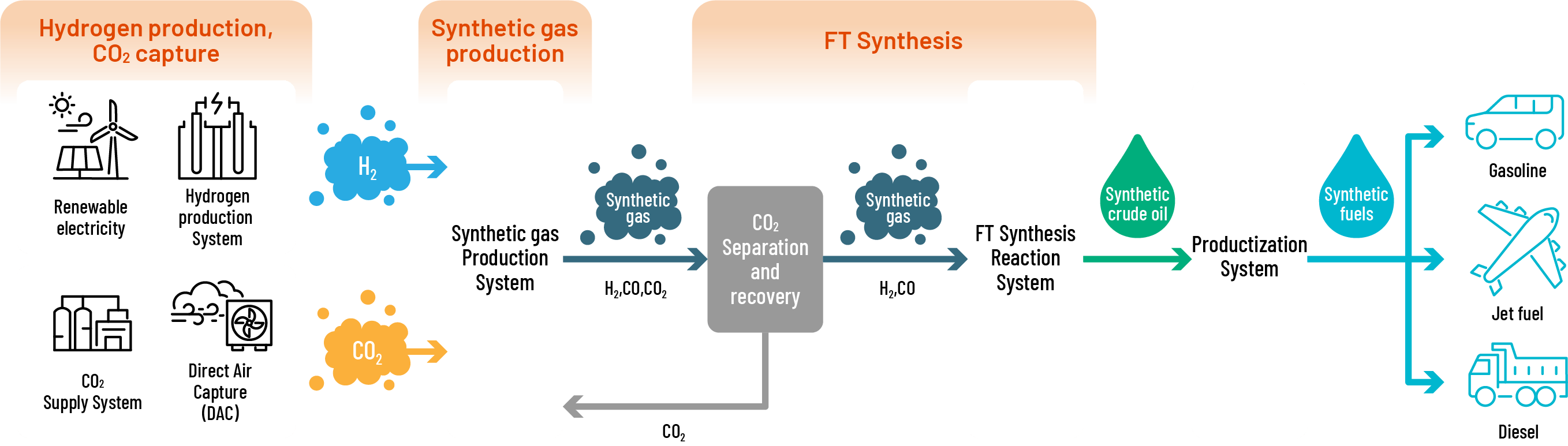

ENEOS’s demonstration plant for production of synthetic fuels primarily consist of three areas: a “Hydrogen production and CO₂ Capture area,” a “Synthetic gas production area,” and an “FT synthesis area.” In the Hydrogen production and CO₂ Capture area, hydrogen is produced by electrolyzing water with renewable electricity, and CO₂ is captured from factory emissions and collected directly from the atmosphere by using special equipment. In the “Synthetic gas production area,” synthetic gas composed of carbon monoxide (CO) and hydrogen is produced from CO₂ and hydrogen, facilitating reaction in subsequent processes. In the “FT synthesis area,” the Fischer-Tropsch (FT) synthesis reaction process is used to produce synthetic crude oil (artificial crude oil) from CO and hydrogen. The synthetic crude oil then undergoes the same processing steps as conventional crude oil in existing productization system to produce fuels such as gasoline, jet fuel, and diesel. Its quality is adjusted to meets the same standards as conventional fossil fuels before being supplied to vehicles.

This project is conducted under the “Green Innovation Fund Project / Fuel Production Technology Development Using CO₂, etc.” of the New Energy and Industrial Technology Development Organization (NEDO).