Completion of a synthetic fuels demonstration plant in the Laboratory!

Japan’s first plant capable of integrated manufacturing from raw materials

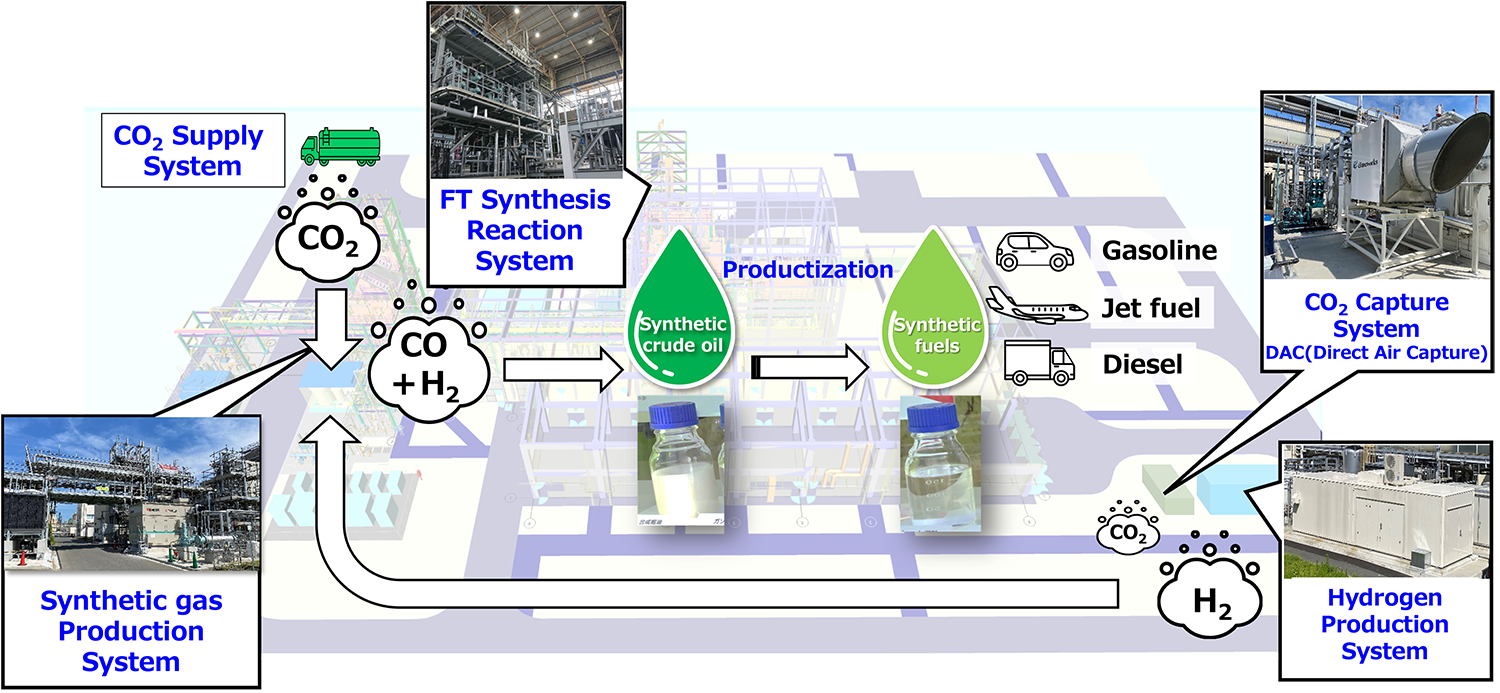

Aiming to achieve carbon neutrality in the transport sector, including aircraft, automobiles, and other vehicles, we are developing a synthetic fuels production process using carbon dioxide (CO2) and hydrogen as raw materials. With the support of the Japanese government, we are proceeding with scale-up demonstrations toward social implementation*. In 2024, we constructed a demonstration plant within our research laboratory, which began operation in September of the same year, capable of producing one barrel (one drum, approximately 159 L) per day.

*This project is part of the Green Innovation Fund Projects of Development of Technology for Producing Fuel Using CO2, etc. commissioned by the New Energy and Industrial Technology Development Organization (NEDO).

As the first of its kind in Japan, this demonstration plant is capable of integrated production from raw materials. This includes supplying CO2 and producing CO2-free hydrogen, using them to produce synthetic gas through the reverse water gas shift reaction, and producing synthetic fuels through the Fischer-Tropsch (FT) synthesis reaction and the upgrading process. Our use of green energy to produce CO2-free hydrogen through water electrolysis is also a first in Japan when producing synthetic fuels. Moreover, our plans include using CO2 captured from air through the Direct Air Capture facility manufactured by Climeworks AG (Switzerland) as part of the plant’s raw materials.

Scaling-up from the lab

Even before the trend toward carbon neutrality began in earnest, we began the research and development of the technology for synthetic fuels production. Starting with a small facility with a production capacity of around 30 mL per day, we have refined our technology through repeated experiments. Through meticulous design and construction to ensure the desired performance, we successfully scaled up our equipment to a plant with a total floor area of 1200m2. With the aim to establish a synthetic fuels production process as soon as possible, we will continue to identify issues and gain further knowledge on how to improve the efficiency and scale-up technologies through continual experimentation on the demonstration plant.

A few words from one of the persons in charge

Two and a half years after the start of the project in 2022, we have reached the end of the construction and the start of the operation of the plant. I was filled with delight when the first drop of oil was obtained from the plant as the result of the ideas and ingenuity of everyone involved. As our next move, we will continuously operate this plant, one of the largest in the history of the laboratory, with the aim of manufacturing products and identifying technical issues. While paying close attention to safety, we will continue to take on the dual challenges of “research” and “production” as we aim for practical application.