Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) is a technology that performs numerical simulations and predicts phenomena by solving equations that model fluid flow and heat transfer by computer. It is an attractive experimental method since it lowers the cost and time needed for collecting data compared with actual experiments while acquiring large amounts of data.

With the aim of achieving both “a stable supply of energy and materials” and “the realization of a carbon-neutral society,” ENEOS is researching and developing a variety of technologies putting simulation technologies to work.

We are developing our own CFD technology that we will use not only for raising efficiency and reducing risks toward a stable supply of energy and materials but also for developing technologies in the fields of hydrogen (Direct MCH®), synthetic fuels, and biofuels toward a carbon-neutral society.

Use in hydrogen (Direct MCH®) field

ENEOS is developing Direct MCH® technology as an upstream process in a CO2-free hydrogen supply chain.

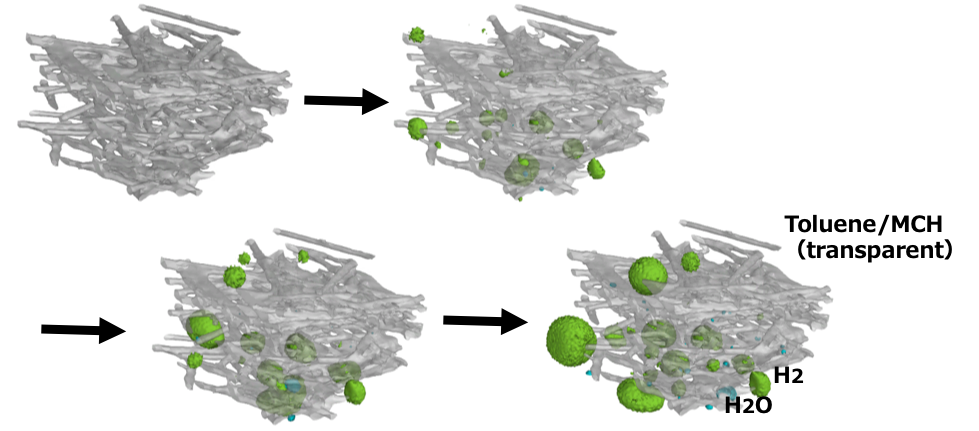

If water transported from the anode in an electrolyzer prevents the toluene from permeating the cathode catalyst layer, hydrogen will be generated as a by-product thereby decreasing Faraday efficiency in MCH production. We therefore performed a CFD analysis to study a microstructure applicable to the diffusion layer on the cathode side.

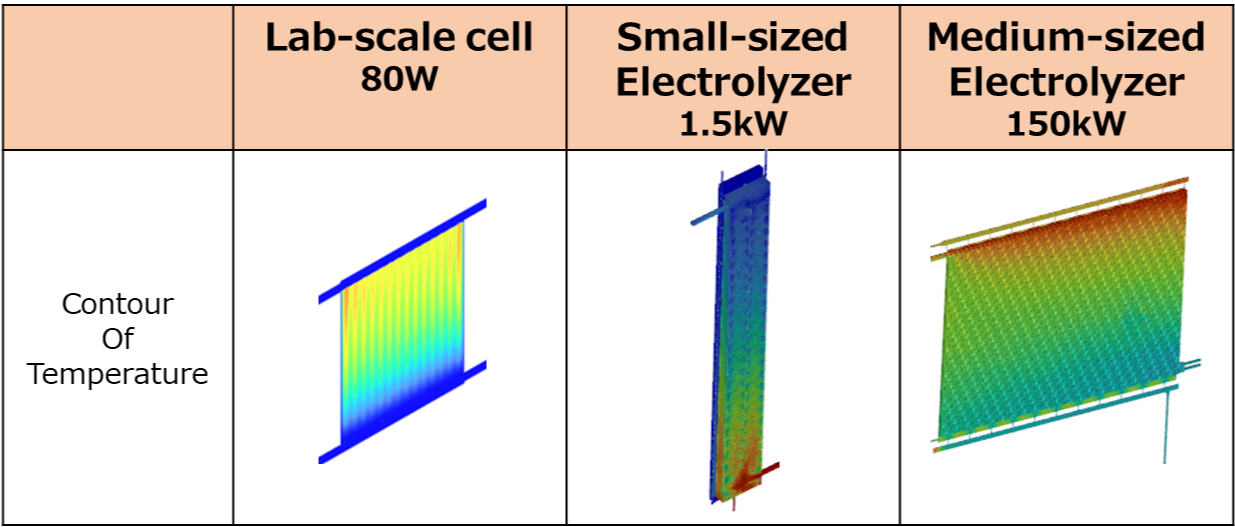

In addition, we successfully scaled up from a lab-scale cell to a medium-sized electrolyzer. In this process, we created models for each type of electrolyzer, performed a CFD analysis of fluid flow and thermal flow for each, and reflected results in electrolyzer design.

We will continue to apply CFD technology toward “a stable supply of energy and materials” and “the realization of a carbon-neutral society.”